Editor's Note: Canoes of this style would have been the basis for the early design efforts of most of the region's canoe industry. Gerrish, Morris, White, Carleton, Old Town, and many other famous canoe companies were founded on the banks of the Penobscot river at a time when bark canoes similar to this one were still in common use.

Canoe from the Penobscot River

By Wendell S. Hadlock And Ernest S. Dodge

The Peabody Essex Museum, Massachusetts, 1948

Reprinted from pages 289 through 301 of The American Neptune Volume VIII, No. 4, 1948.

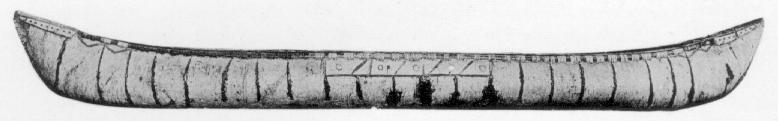

Interior view of the Penobscot Canoe [Catalogue E 14268] in the

Peabody Museum of Salem

Shows ribs, sheathing, thwarts, inside of gunwale, and

bulkhead.

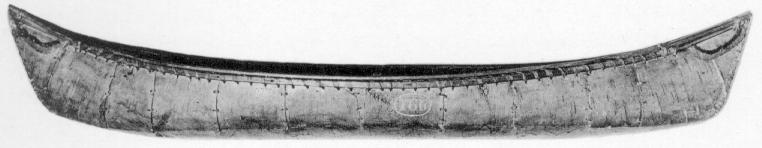

For many years a Penobscot Indian birch bark canoe has been displayed on top of the cases at the south end of East Hall in the Peabody Museum of Salem Massachusetts. The label conservatively states that it is a canoe, gives the tribe, and adds the information that it was given to the East India Marine Society in 1896. Little notice was taken of the canoe, and it was not thought to possess any particularly historical merit beyond being a representative example of that particular type of craft. The early accession date, however, combined with certain features, the decorative designs and colors used for ornamentation, and the materials and workmanship, indicate it to be one of the oldest known Penobscot birch bark canoes.

The canoe first appears in our records in the manuscript donation list of the East India Marine Society for 1826. In the printed catalogue of 'the museum of 1831, it is listed as number '3674, Indian Canoe, from the Penobscot River.' The craft is now recorded as E 14268, in the Ethnological Catalogue of the Peabody Museum of Salem.

The canoe was badly in need of repair and in February 1947 it was decided to restore it. During the next two months, Mr. Hadlock replaced most of the spruce lashings and otherwise repaired the canoe so that it should last for another hundred years. It was during this period of reconstruction, and while investigating other bark canoes for comparative techniques of manufacture, we discovered that, to our knowledge, no other canoe approached this craft in age by at least fifty years. Thus it appears that our canoe is the oldest known of its type in existence from the Maine-New Brunswick area and therefore of unusual historical and ethnological significance.

Canoe building was one of the most extensive and important skills among the Indians of Maine and the Maritime Provinces where it furnished an easy, convenient mode of travel, and without which the economic life of the hunting nomadic Indians would have been greatly restricted. Canoes, light and sturdily constructed and easily carried by one person overland between navigable waters, were eagerly sought by those Indians living south of the range of white birch as they facilitated passage up and down the many rivers and streams. The importance of the birch canoe to the economic life of Indians during the exploration period, and to white men in the early colonial and fur-trading times, is forcibly brought to our minds by the many historical accounts mentioning its use as an aid in traveling and as a means for shipping supplies to and from remote posts.

Although there are many references relative to the use of native water craft in the journals by the earliest explorers and missionaries to northeastern North America, the information regarding the design and construction of such boats is very limited or totally lacking. The earliest mention of boats in this region is by Jacques Cartier, who recorded in his voyage of 1534 that he met Indians in the mouth of the Bay of Chaleur who were traveling by boats from one shore to another.1 Father Biard, writing of the Indians of Port Royal at a much later date, said, 'They make the canoes, that is, skiffs of marvelous rapidity, out of bark; ...' and that, 'These canoes are so made that, if you do not sit very straight and steady, they immediately tip over; ...'2

With the coming of the first settlers and fur traders, more attention was given to the native inhabitants and their material culture, which is reflected in the writings of that period. Among the early observers was a Nicolas Denys who from about 1632 to 1650 lived at Saint Peters in Cape Breton and at Nipisiguit, New Brunswick, where he observed and made notes on the customs of the Indians with whom he traded. In his writings we find the first detailed description of an Indian canoe. He said:

For making their canoes they sought the largest Birch trees they could find. They removed the bark of the length of the canoe, which was of three to four fathoms and a half [in length]. The breadth was about two feet in the middle, and always diminished towards the two ends, failing away to nothing. The depth was such that for a man seated it came up to his armpits. The lining inside for strengthening it was of slats, of the length of the canoe and some four inches broad, lessening towards the ends in order that they might match together. On the inside the canoe was lined with them completely, as well as all along it from one end to the other. These slats were made of Cedar, which is light, and which they split in as great lengths as they wished, and also as thin as they pleased. They also made from the same wood half-circles to form ribs, and gave them their form in the fire.

For sewing the canoe, they took roots of Fir of the thickness of the little finger, and even smaller; they were very long. They split these roots into three or four parts, that is the largest ones. These split more easily than the Osiers used in making baskets. They made these into packages, which they placed in the water for fear lest they might dry up. There were also necessary two sticks of the length of the canoe, entirely round, and of the thickness of a large cane, and four other shorter sticks of Beech. All these things being ready, they took their bark and bent and fixed it in the form the canoe should have; then they placed the two long pieces all along and sewed them to the rim inside with these roots.

To sew they pierced the bark with a punch of pointed bone and passed through the hole an end of the wicker, drawing and tightening the stick as closely as they could against the bark, and always enwrapping the stick with the wicker so that they were in contact with one another. The sticks being well sewed on all along, they placed also the smaller pieces of beech crosswise, one in the middle, entering at its two ends into holes made in the pieces with which the canoe is rimmed, and three others in front of it, distant a half fathom from one another, which lessened in length with the shape of the canoe. Three others also were placed backward at the same distances. All these pieces entered also at their ends into holes which were made in the pieces sewed all along the canoe, to which they were so firmly attached on both sides that the canoe could neither enlarge nor narrow.

Then are placed in position those big slats with which they lined all the interior of the canoe from top to bottom, and they were all made to touch one another. To hold them in place, they put over them those half-circles, the ends of which were brought to join on both sides below those pieces which were sewn all around on the top. They drove these in with force, and they lined all the canoe with them from one end to the other. This made the canoe stiff to such a degree that it did not yield at any point.

There were seams in it, for in order to narrow it at the two ends, they split the bark from above downwards; they then overlapped the two edges one over the other, and sewed them. But to prevent the seams from admitting water, the women and girls chewed the gum of the Fir every day until it became a salve which they applied by aid of fire all along the seams, and this tightened them better than pitch. All this being done, the canoe was finished, and it was so light that a single man could carry it on his head.3

Although Denys' description is a more detailed account of canoe building than the works of later historians and present-day writers, it is lacking in the necessary details for the complete construction of a birch bark canoe of this region. It is of particular interest to note the close parallels of construction followed in canoe building among the Micmac of the middle sixteen hundreds, as recorded by Denys, and the Penobscot of the early eighteen hundreds.4

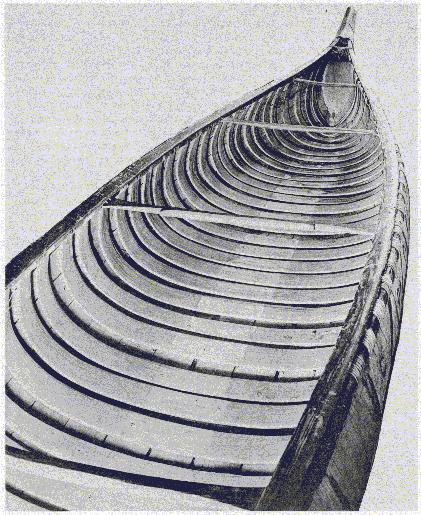

Model of a Malecite from the St. John River reqion [Catalogue E 13150]

This model was given to the Museum in 1803 and is illustrated to show the similarity of profile design to the Penobscot canoe.

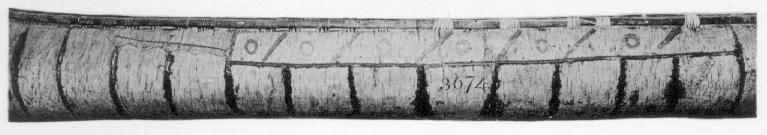

Section in the middle of the Penobscot Canoe [Catalogue E 14268] on the starboard side

Shows side reinforced by piece of birch bark with scalloped edge as a guard and the decorated insert.

The following description is the result of a detailed study of the early Penobscot canoe shown in Plate 27, and also illustrated by plans drawn to scale (Figure 1).5 This study has revealed many details not hitherto published and supplements the common knowledge of birch bark canoe building.6 The canoe is 19 feet, 7 3/4 inches overall length, by 3 feet, 1 inch greatest beam and is, like most canoes of similar dimensions, made from one piece of bark.

Fig. 1. Lines of the canoe taken off by D. Foster Taylor

As Denys related, the actual construction of the canoe was not, in most instances, undertaken until all materials had been assembled. The bark was the last item to be prepared as it had to be worked in its green state, when it could be bent and laced into the proper shape without great danger of tearing. If a delay in the construction of the canoe could not be avoided, the bark had first to be placed in water to make it supple.

Fig. 2. Details of construction: a. section of rail and spruce root lashings; b. bulkhead; c. cross-section of rail and side; d. stempost; e. peg showing result of strain

The gunwale, with a few exceptions, consists of the rail, the outer protective siding, and a top railing (Figure 2a, c). Some canoes, particularly those made by the Micmac of Nova Scotia, omitted the cap by turning the rail so that the outer protective siding laid facing upward at about a forty-five degree angle amidship, thus performing a dual function of being the cap and the siding. The gunwale, as well as the ribs, stem, bulkhead, and lining or planking, were all made from white cedar (Thuja occidentalis). This material was rifted from the tree and later worked to the desired proportions with sharp cutting implements. In later years after the introduction of iron and steel, the crooked knife was used almost exclusively for wood working. In cross-section, the rail was square and about 1 1/2 inches thick amidship, slightly tapered towards the bow and stern (Figure 3). On the outer and undersides, notches were cut, into which the ends of the ribs were to be fitted (Figure 3b); mortises were also made to receive the ends of the thwarts (Figure 3b). After the rails had been spread to the desired width and held apart by spreaders and the thwarts installed, the ends were secured with cedar bark wrappings.

Fig. 3. Details of construction: a. top rails showing overlap of ends; b. section of inner gunwale showing notches for ribs and mortise for thwart; c. inner gunwale at end; d. end thwart; e. quarter thwart; J. center thwart

The next process in construction was to place the birch bark on a level area with the inner bark down, and kept in position with rocks so arranged that they formed the general pattern of the bottom of the canoe. The outer edges of the bark were then turned upward and held along the rail by stakes driven into the ground. At this time the sheer was determined and the upper edges of the bark were trimmed to conform to the lines of the gunwale, and the gores were made at regular intervals on each side, which permitted the bark to lie snugly against the inner rail. The edges of the gores overlapped about half an inch at the gunwale.

After the bark had been trimmed and otherwise prepared so that it needed no other major alterations, it was securely fastened to the rail by means of wooden pegs which passed through the outer protective siding. It is interesting to note the warped condition of these pegs - a clear indication of the severe strain to which they have been subjected (Figure 2e). The outer protective siding was made of cedar and laid flat against the birch bark (Figure 4). The holes for the wooden pegs in the rail and outer siding were predetermined and made before the actual assembling of the canoe. The pegs passed through the outer protective siding, the birch bark, and well into the rail, and in some cases passed entirely through the rail. After the bark had thus been permanently secured, the pegs were trimmed flush with the outer surface.

Fig. 4. Sketch showing construction and relationship of birch bark to sheathing and ribs

Split spruce root lacings were used in binding the bark more securely between the rail and outer protective siding (Figure 2a, c).7 Denys mentioned that small roots were split into three and four parts, but from our studies it appears that the canoe builders of this region used roots approximately three-eighths of an inch thick which they split down the center and trimmed to remove any irregularities. We have noted that the roots of smaller diameter were used toward the ends of the craft.8 The average length of the lacings used on the gunwale was about 10 feet.9 The end of the lacing was feathered and inserted between the bark and outer rail. Lacing was done from the outside inward and the standing part was brought up over the railing. As the root was brought up over the gunwale, it was drawn tight. This forced the outer and inner rails together and securely held the birch bark in place. Each stitch did not necessarily pass through a separate hole in the birch bark as the perforations must not be close together.10 The number of stitches depended on the length of the root - the average was eight. The interval between lacings averaged from 3 to 4 inches. When each section of lacing was completed, the end was rove under the last three or four turns of that section. The completed lacing presented a neat and well ordered appearance and each turn laid closely against the other with no overlapping or crossing.

Upon completion of the gunwales, the gores were trimmed to insure uniformity in the overlapping of the bark and were sewn with split root. The root lacings used in the gores were much smaller than those on the gunwales and two types of stitches seem to have been employed. The preference of one stitch over the other appears to have been dictated by the strain to which that particular part of the canoe would be subjected. The gores forward and aft of the quarters were laced with an overhand clockwise stitch from the bottom of the gore to the rail. A double thread cross-stitch was employed on the gores at the bilges amidship which terminated about a foot below the rail. From this point to the rail a single overhand stitch was employed. The cross-stitch pattern was made with two, split roots, one laced overhand clockwise and the other overhand counterclockwise, with the lacings crossing at the seam.

A lining or sheathing of very thin strips of rifted cedar was next placed inside the canoe. The thin planking was trimmed along the edges, permitting each piece to fit closely against the other without overlapping. The planking was fitted amidship and held in place by a rib, and then fitted towards the ends of the canoe, being held in place by ribs inserted at more or less regular intervals. The remaining ribs were later added, after being trimmed to fit tightly into the notches which were previously cut in the rail. Each rib was driven into position working from amidship towards the bow and stern. The ribs had been previously roughed into the general length and width and bent into a half circle or to parabola form, depending on the position the ribs were to occupy in the canoe. The molding of the ribs took place soon after the wood had been rifted from the log, as thin green cedar splits could easily be molded into the desired shape.11

Although the planking extended to the ends of the canoe, ribs could not be fitted into this narrow space. Consequently the bow and stern were very weak structurally. To insure a certain degree of rigidity, a stem of cedar was braced against the last ribs of the bow and stern. About two-thirds of the entire length of each stem was made triangular in cross-section and the remaining portion was half round. The triangular part of the stem was split into seven or more parts and wrapped with cedar bark. The stems of the Penobscot canoe were split into seven and nine parts respectively (Figure 2d). The purpose of splitting the stem was twofold as it facilitated bending the wood into the proper shape, and permitted the builder to pass the split root lacing of the bow and stern through the stein. The upper end of the stem was tied in securely with the rails. The birch bark of the bow and stern was trimmed so that the sides met without overlapping and was laced with a double overhand stitch similar to the lacings of the gores at the bilges. The bark forward and aft of the point where the inner rails converge was brought up and overlapped on a line with the rails, thus making the bow and stern completely decked over. The overlapping of this bark was sewn into position without any semblance of regularity. The ends were then packed with cedar shavings, which performed the dual function of keeping the shape of the ends and giving buoyancy to the canoe when filled with water. The bulkhead (Figure 2b) was then forced into position by stepping the lower end into a notch which had been previously cut in the stem. The bulkhead fitted tightly against the planking and, in addition to strengthening the canoe, kept the packing in place. As an additional protection against leakage, particularly in rough water, flaps of birch bark were placed on the bow and stern.12 They were installed over the outer bark of the canoe and under the outer protective side rails. Each extended from the bulkhead to the extreme end of the canoe.13

The top railings (Figure 3a) were the last installed and unlike the inner gunwales, extended the entire length of the canoe. They were attached by means of wooden pegs which were driven through the top rail and well into the inner gunwale. To further strengthen and secure the three-piece gunwales, several root lashings were employed - one each at the extreme ends and another at the convergence of the inner gunwales and the upper end of the bulkhead.

The final step in preparing the canoe for the water was pitching the seams. Any of the soft-wood pitches could be made suitable for this operation. The pitch was usually boiled and mixed with some form of grease to give elasticity. It was applied when hot and pressed into the seams with a dampened stick, or with the hands, which had been first dipped in water. Particular attention was given to the bow and stern seams and it was found on this Penobscot canoe that small strips of cedar and birch bark had been mixed in with the pitch. It appears that successive coatings of pitch were placed over these seams and before each coat had cooled, small strips of bark were imbedded. A coarse, open-weave cloth used on the bow and stern was undoubtedly the result of later repairs.

Birch bark canoes in the Penobscot River area were usually decorated either by bark engraving or painted designs. Another form of decorative art less commonly used, the cutting of geometrical patterns in the lower edges of the stem flaps and paddle guards, has been found on a few canoes of this area. Except for one incident - the zigzag cutout on the lower edge of the paddle guard (Plate 27) - the entire decoration of the canoe under discussion is executed with black and red paint. The flaps on the bow and stern are painted black on the top and the lower portion on each side is outlined in red, thus forming a panel containing a single row of red dots. The bow flap has eight dots on the starboard side and nine dots on the port, and the stern flap has seven dots on the starboard side and eight dots on the port. On both the port and starboard side of the bow and stern are painted zigzag lines extending for about 18 inches from the apron. The upper portion of this line is in black and immediately below and parallel with it is a red line. The inserts amidship are also decorated. The starboard insert is divided into seven sections by diagonal red and black lines (Plate 27), the red being always above and the black below. Each section, except one, contains a single black and red circle, the red forming the outer circumference of the circle. The bark insert on the port side has similar decorations, but is divided into five sections, which is undoubtedly due to this insert being much shorter than that of the other side.14

All the elements in the simple decoration used on this canoe can be considered old and without doubt aboriginal. The straight incised zigzag lines of similar decorative pattern have been found archaeologically on pottery and bone work in the Penobscot River region. The dot decoration, as evidenced on the aprons and side panels, is very old and widely distributed in North America. It is commonly found in the general northeastern area on Eskimo bone work, Naskapi caribou skin painting, and in all the various art techniques used by the Wabanaki and Iroquois tribes. The simple decorative art used on this canoe is in sharp contrast to some of the later more complex art which may contain many European elements.

A comparison of the line drawing (Figure 1) with many illustrated canoes of this region will bring forcibly to the mind of the reader that there has been a tendency on the part of the illustrators of the northeastern woodland birch bark canoe to emphasize the ends. They have exaggerated the bow and stern to appear as if the ends swept upward and back over the gunwale. This conclusion was also reached by Mrs. Eckstorm, who wrote, 'The ends of the wooden gunwale mark the greatest extent and greatest length and greatest height of any part of the canoe - a point often disregarded by artists.'15 Lucius L. Hubbard, also commenting on the same subject, had this to say, 'The ends curve more or less according to the fancy of the builder, but seldom according to the fancy of any illustrators.'16 From a comparative study of models and canoes of the Penobscot, Malicite, and Passamaquoddy, emphasis was not placed upon the high stern and bow until recent times. It seems that this innovation is, in the Maine region, when it occurs, a comparatively modern adaptation of Ojibwa bows and sterns and used only on those later canoes sold for commercial purposes.

Many canoes of the Penobscot and Passamaquoddy Indians have a narrow strip of birch bark amidship, which is usually highly decorated, either with painted designs, carvings., or etchings. This insert may have the dual purpose of being a reinforced panel inserted over the gores amidship and as a panel for decorative purposes. The inserts on the canoe under discussion are 6 feet long and 5 inches wide on the starboard side, and 3 feet 10 inches long and 5 inches high on the port side. The inserts amidship are not a distinctive feature for canoes of this region. The Penobscot canoe also has an overlay of birch bark forward of the position taken by the stern paddler. This overlay is decorated with a triangular edge and was undoubtedly a protection and reinforcement to the sides of the canoe against the sweep of the paddle.

Although this canoe appears to have been in use for some time before being presented to the East India Marine Society Museum and was constructed similar to other canoes from the same and adjacent regions, it has one structural weakness. The inner lining of the rifted cedar joins on the center rib, or the rib forward and aft of the center rib. The making and breaking of the inner planking so near the center rib had caused this canoe to become strained and broken amidship. A check of other canoes of this region reveals that this structural feature is not unique in many of the Indian canoes over 16 feet in length. Consequently, the bark becomes strained and in most cases breaks across the bottom from one gunwale to the other.

Footnotes

1 J. P. Baxter, Ed., A Memoir of Jacques Cartier (New York., 1906), p. 103.

2 R. G. Thwaites, Ed, The Jesuit Relations and Allied Documents (Cleveland, 1896-1901), I, 77 and 159.

3 N. Denys, The Description and Natural History of the Coasts of North America, edited by W. F. Ganong (Toronto: The Champlain Society, 1908), PP. 420-422.

4 The Micmac, with whom Denys was probably most familiar, occupied the eastern portion of the Gaspe Peninsula and northern Nova Scotia; the territory of the prehistoric Penobscot has been generally conceded by the present-day ethnologists to be confined to the watershed and bay regions of the Penobscot River.

5 The authors are greatly indebted to Mr. D. Foster Taylor, who prepared the plans of this canoe shown in Figure 1. The drawings for Figures 2, 3, and 4 were made by Mr. Robert Morse.

6 Both Eckstorm and Speck contain extensive accounts of Penobscot canoes obtained from Indian informants. These standard sources should be consulted for other details relating to the subject. F. H. Eckstorm, 'The Handicrafts of the Modern Indians of Maine,' Lafayette National Park Museum Bulletin, III (Bar Harbor, 1932), 55-64. F. G. Speck, Penobscot Man (Philadelphia: University of Pennsylvania Press, 1940), pp. 57-68.

7 Spruce root was not exclusively used and other soft wood roots were sometimes substituted.

8 The prepared root is kept moist to retain its flexibility.

9 A suitable root from which lashings may be made is found in the coniferous forests on the, edges of swamplands, or other areas where the root is not required to go deeply into the ground to secure the necessary moisture and nourishment.

10 Perforations in the birch bark were made by means of bone awls prior to the advent of the explorers and traders.

11 Denys mentioned that the Indians formed their ribs in fire. It may be probable that Denys saw Indians steaming ribs preparatory to molding them into shape, as the material may have dried and was no longer pliable. The wood is first soaked in water until it is thoroughly saturated, and then held over a fire, which causes the water in the wood to turn into steam, thus rendering the wood pliable.

12 Speck, op. cit., p. 61, found that these pieces were called, figuratively, 'diaper' or 'breechcloth' by the Penobscots at Indian Island.

13 The original flaps of this canoe had been removed from their original position before 1826 and the present ones were placed over the top gunwales and secured into position with iron nails. Faint outlines of the original position occupied by the flaps may be seen at both the bow and stern of the canoe.

14 Other, related, styles of decoration on these inserted panels are shown on the two canoes figured by Speck, op. cit., p. 58.

15 Eckstorm, op. cit., p. 57

16 L. L. Hubbard, Woods and Lakes of Maine (1884), P. 115.

This article originally appeared on pages 289 through 301 of the Volume VIII, No. 4, 1948 edition of The American Neptune and is reprinted here by permission. The Peabody Essex Museum can be found at East India Square, Salem, Massachusetts 01970 or by email at pem@pem.org.

Navigation Aids